Water Repellent Agents

Hydrophobization – What Is It?

Hydrophobization means surface treatment with water repellent agents.

Hydrophobization is giving the material the ability to repel water. At the same time, the material retains the ability to “breathe”, in other words, to pass gases and vapors. This is the main difference between hydrophobization and waterproofing (sealing). In the case of waterproofing, the surface of the material is completely blocked. Accordingly, hydrophobization is used where multiple, but temporary (hours, days) water effects on building materials are expected. To protect structures under constant exposure to water, especially under pressure (various tanks, dams, etc.), hydrophobization can only be used in combination with waterproofing.

How Does It Work?

Operation Of Silicon Water Repellent Agents

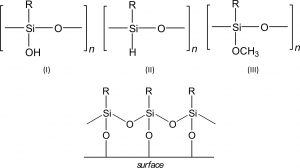

All industrial silicon water repellent agents based on the organo- polysiloxanes are the oligomeric compounds or their aqueous or nonaqueous solutions. Organopolysiloxanes used for the water repellency treatment (hydrophobization) of construction materials contain groups that are able to bind with surface of the material chemically: Si–OH, Si–H, Si–OCH3, and Si–OC2H5. Other kinds of active groups are almost not in use due to the complexity and high cost of production or to the low stability of corresponding compounds. Besides, the molecules of used organopolysiloxanes are bound to contain water‑repellent fragment R (alkyl or aryl group, for instance). R are CH3, C2H5 or C6H5 mostly. Other kinds of R are almost not in use due to the above‑mentioned reasons.

Thus, the industrial organopolysiloxane water repellent agents contain the following fragments: (I), (II), (III). The substances (II) and (III) convert to the substance (I) under the action of moisture contained in treated materials and of alkaline or acid traces (a polymerization runs simultaneously). The active groups Si–OH of the substance (I) readily react with the surface of construction material forming a chemically bound coat. Outer side of such a coat consists of water‑repellent groups.

In fact, the interaction process is more complex inasmuch as organopolysiloxane molecules are rather coils, spirals, and “clews” than lines.

Due to brush of groups R the surface of treated material ceases moistening by liquid water as much as wax or paraffin. Nevertheless, spaces between groups R are large enough and gas exchange (oxygen, water vapor) between the surface and surroundings is not affected: the surface breathes.

Careful Protection Of Wood Articles:

HydrophobNeo Water Repellents

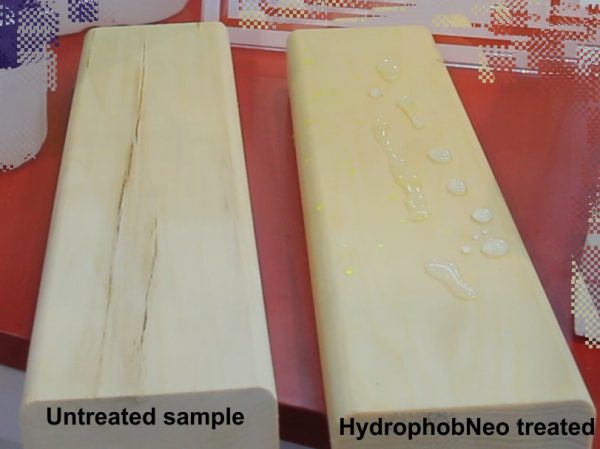

It is well known that wood has low enough resistance towards water and moisture action resulting in swelling and buckling and cracking after drying. Even more critical may be the influence of water on plywood, wood-chip boards and similar materials – even after one wetting these materials can deform, flake and lose their market properties.

Moreover, wet wood is a good media for growth of mould, fungi and algae, which first form disgusting white, black or green spots at the article surface and then destruct it quickly enough. Usually wood is protected against water influence by impregnation with drying oil or coating by lacquers or paints, these ways of treatment deprive wood of its main advantage – the ability to “breath”. The alternative way is the wood treatment with HydrophobNeo water repellent agents. These compositions decrease wood wetting without eliminating air- and moisture- exchange ability of wood

FAQ

About HydrophobNeo Water Repellent Agents

- What materials should be treated with HydrophobNeo water repellents?

HydrophobNeo-S & -L water repellents are suitable for all silicate building materials: concrete, silicate and ceramic bricks, natural and artificial stone, aerated concrete, foam concrete, paving slabs, gypsum, etc.

The water repellent agent HydrophobNeo-W is suitable for wood products and materials based on it: plywood, chipboard and fiberboard.

The water repellent agent HydrophobNeo-G is suitable for all types of glass surfaces, especially for automotive glasses.

- Are the water repellent agents HydrophobNeo suitable for the treatment of articles made of plastic, metal or fabric?

No, HydrophobNeo compositions should not be used for the treatment of articles made of any polymeric materials (plastics), of any metals and also of textiles. They are suitable for waterproofing silicate building materials, as well as wood & glass (see above).

- How long do water repellent properties last?

The water-repellent properties of the material treated with HydrophobNeo water repellent agent last from 3 to 10 years or more, depending on the conditions of application (the type of HydrophobNeo composition), operation, and the initial state of the material prior to treatment.

If increased mechanical stress is expected (for example, while using hydrophobic paving slabs in crowded places), then repeated treatment is recommended after 3 years of application.

- Does the film exist on the surface of the material treated with water-repellent agent HydrophobNeo?

No, when the surface is hydrophobized, the film is not formed. The vapor permeability of the material is fully preserved.

The water repellent agent HydrophobNeo is absorbed into the material; the molecules of the active substance interact with the surface layer of the material. As a result, a kind of “barrier” is formed, the distance between the molecules of which does not prevent gas exchange.

- How to apply HydrophobNeo water repellent agents?

HydrophobNeo water repellent agent is applied with a roller, brush or spray in accordance with the instructions. Before treatment, it is recommended to carry out a trial application to control the consumption and compatibility of the water-repellent agent with the material.

- Is it possible to paint the material treated with HydrophobNeo water-repellent agent?

All further finishing of the waterproofing surface requires non-aqueous materials.

- What is the depth of penetration of HydrophobNeo water-repellent agents?

The water repellent HydrophobNeo-L penetrates to an average depth of 1/4 In (about 6 mm). HydrophobNeo-S water repellent penetrates to a depth of 1/4 to 1 In (of 6 to 25 mm), depending on the porosity of the surface. Thus, light mechanical damage to the hydrophobic surface (scratches, chipped material) will not affect its water repellency.

- Is it possible to wash the hydrophobic coating from the surface of the material?

HydrophobNeo water-repellent agent creates a protective layer inside the material, the thickness of this layer is on average 1/4 In. (about 6 mm). That is why the composition cannot be washed off the surface; over time, the “lotus” effect on the surface may decrease, but still moisture will not get into the material. We recommend repeated application on average once in 5 years. This allows you to extend the service life of the building significantly.

- Can a hydrophobic surface become slippery?

No, the HydrophobNeo compositions do not create a slippery effect; also the color of the HydrophobNeo treated materials does not change.

- Will the appearance of the material change after hydrophobization?

No, after treatment with the HydrophobNeo water repellent agent color & texture of the material remain unchanged. In some cases, the color of the treated surface becomes more contrast.

- Is it possible to apply compositions to a wet surface?

Yes, the HydrophobNeo-S water repellent agent may be used for the treatment of wet surfaces.

- At what temperature can the material be treated with water repellent?

HydrophobNeo water repellent agents can be applied at temperatures above minus 10°C (+14°F).